1. Working Principle of a Dry Cooler

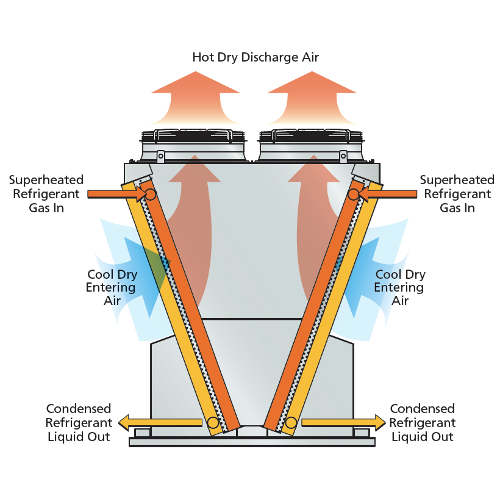

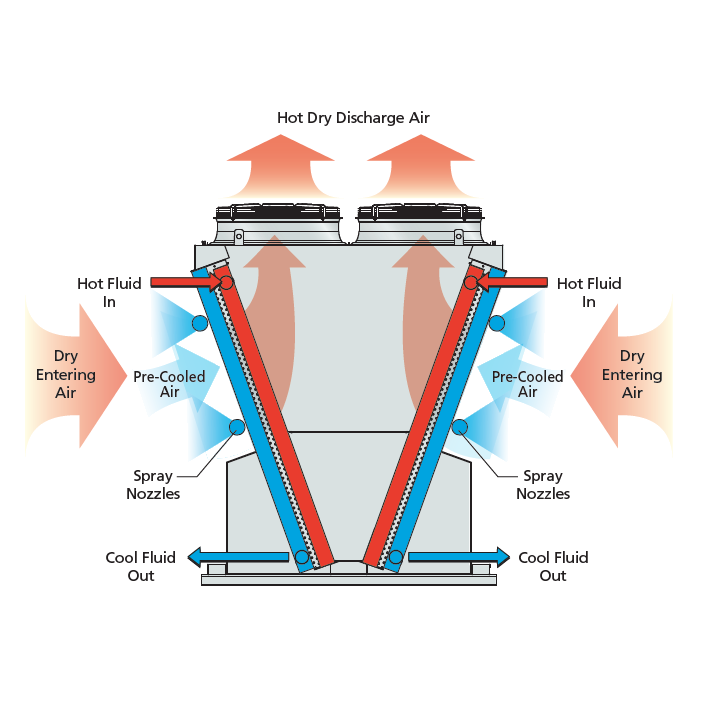

A dry cooler works by utilizing the heat dissipation properties of metal to cool down hot water or oil through physical heat transfer. First, hot water or oil flows into metal pipes, typically made of refined copper. The copper used has a purity of up to 99.9%, with a thermal conductivity of about 398 W/m·K. A fan located at the top of the dry cooler creates airflow by generating a pressure difference. This causes air to pass over the copper fins, which in turn cools the pipes. As the hot water or oil travels through the pipes, it gradually cools down to a lower temperature.

2. Heat Dissipation Efficiency of a Dry Cooler

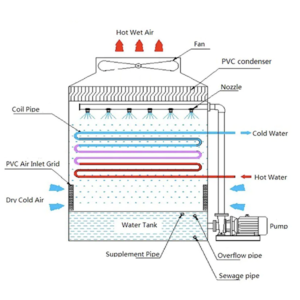

Several factors influence the cooling efficiency of a dry cooler. These include the ambient temperature (dry bulb humidity), the length of the pipes, and the fan’s airflow. In dry desert areas, cooling efficiency can decrease. To counteract this, a spray system can be added, which increases the humidity in the air and reduces the dry bulb temperature. This setup can lower the hot water or oil’s temperature by an additional 3-5°C. However, in areas with high humidity, the benefits of the spray system are not as effective.

3. Water Consumption

Because the dry cooler is a closed-circulation system, internal water evaporation is nearly nonexistent. However, when a spray system is added, some water consumption occurs. The system can be adjusted based on the local climate and cooling needs. Water usage ranges from a few liters to several dozen liters per hour, depending on the specific setup. Both groundwater and tap water can be used for the spray system, helping to minimize operational costs.

4. Suitable Environments for Dry Coolers

Dry coolers are ideal for areas with limited water resources or high water prices. This includes deserts, arid regions, or industrial zones with restricted water supply. For example, in the Middle East, where high temperatures are a concern for mining operations, dry coolers with spray systems are often recommended. If summer temperatures in your area regularly exceed 50°C, it’s advisable to select a dry cooler equipped with a spray system or one that is designed for high-temperature performance.

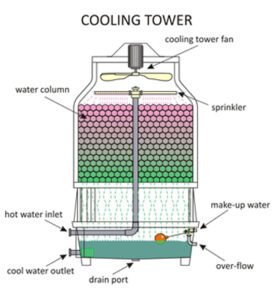

On the other hand, if you’re located in an area with abundant water resources, you may consider a dry-wet water tower (also called a closed water tower). While these consume more water, they offer better cooling efficiency at a lower cost. For short-term Bitcoin mining, open water towers may also be an option. These systems consume more water and provide less cooling capacity, making them best suited for regions with ambient temperatures below 35°C.

5. Dry Cooler Selection

At HashZebra, we customize dry coolers based on your region and the number of miners. Our product range includes various sizes and pipe lengths to fit your specific requirements. Standard options include 50kW, 120kW, 200kW, 400kW, 500kW, 600kW, 700kW, 800kW, 1000kW, and 1200kW. Although larger coolers require more space, we design them to fit inside containers, making transportation, loading, and unloading more convenient.

-212x300.png)